I'm finally re-vamping my cluttered, dark, dis-organized shop on a budget. Big projects need to be broken into manageable pieces. Here's the process I'm going through to make sure my budget shop upgrade comes together right.

I'm finally re-vamping my cluttered, dark, dis-organized shop on a budget. Big projects need to be broken into manageable pieces. Here's the process I'm going through to make sure my budget shop upgrade comes together right.

I've been thinking about my shop upgrades for a while now. I've sketched, measured, dreamed, and worried about it for years, and now that I'm actually starting the build it's time to break it into pieces manageable enough to get done without going bonkers. My uncle told me a few months ago "make sure you design it for when you're in the middle of a project, not for when everything is all neat and tidy." That's important, because it doesn't matter if it looks good but can't be functional. I've thought quite a bit about work flow, and design. Tools are spaced far enough apart to keep from overlapping, and all counters are the same height so materials can move from one place to the other easily.

The key to a good plan is to start at the end and back into it, so I've taken some time to really get into the project with a detailed SketchUp model. Here's a look at the finished (hopefully) project, complete with scale tools:

Now the key is that I've built each component to the point that I have a material list for each piece of the cabinet. I designed them separately and then imported into the model to be able to measure and plan each piece at a time. After that, I broke the project into 4 Phases to make sure I have the materials needed for each portion of the project. Here's what that looks like:

Now the first step over the next week will be to completely destroy the shop. Everything will come off the wall, off the floors, and out of the shelves so I can deep clean all the dust out and only keep what I need. This is a huge and important first step that will allow me time to figure out what junk I've kept for way too long. After that, we'll jump into the first phase:

Phase 1: I am planning on tackling the wall first to start the organizational process. By adding a huge amount of open space on the wall, I will be able to clear out the shelves and start to get things into their place. I will also be painting the walls, and re-routing the dust collection and air compressor line so this phase is where the momentum for the next few comes in. $130 in materials

Phase 2: Building that tool island will be the next step, giving me a place to park the tools that crowd my countertop right now. Right now, the mobile base is a pain, and honestly it looks pretty sad. I especially like the place where I've put the planer, out of the way but still useful. By leaving a space open below the top counter, and installing casters on the island I can dimension and finish wood with full out-feed support. Not sure how well I will like the low position of the tool, but at over 100lbs, I know that I don't like hefting onto my bench to plane a few boards. The challenge of this step will be to set up power and dust collection in a way that is accessible but not in the way. I'm tired of stepping around cords and hoses on the ground, so suspended from the ceiling is likely the way to go but I will need to keep clearance for the garage door. $120 in materials.

Phase 3: This is the largest phase of the project for sure, with a full tear out of existing shelves and a warped bench top. I will also be embedding my radial arm saw into the countertop for a large supported cutting surface. That sure beats the current set-up above with all that wasted space. I've designed the whole thing into modules 4 of which all have the same basic carcass with different face frames and doors. I'll build 8 drawers, about 12 doors, wire up about 6 outlets, and then lay a huge countertop on the entire thing. $300 in materials

Phase 4: My last phase will be all of the wrap-up that comes with a project, clean-up, rearranging, and final touch-up. I will be cutting down and re-sizing my current 4x8 workspace to about a 4x5 space with the table saw on one end and the router table on the other. I'll be working on some dust collection routing, and adding face frames and doors to the frame to stiffen it up and provide some dust-free storage space. $50 in materials

So my total budget for this project is about $600 and that's pushing it. That's another benefit of breaking the project up into smaller phases, you have the ability to work as the budget (and time) allows, but you don't have to live with half-finished projects for too long.

Final thought:

After all the planning, I realized that I haven't taken into consideration 2 important items: sheet good and clamp storage. Both items have the potential to take up some serious room, so I'll be doing a bit of wrangling (or may just build a bit of protected storage outside). Take the time to sketch out detailed plans on the process and pieces to get a good idea of where the challenges are and also where things can be broken up into manageable pieces. I love SketchUp for this, it's a free and very robust program that gives the ability to develop something in 3D detail that is great for planning and visualizing a space. I talked last week about learning some of the basics here, and look for our piece on advanced model development for woodworking next week.

![credit: Kinarri Leather [http://www.kinnarileather.com/] Leather Tools](http://assets.manmadediy.com/photos/26567/image_large.jpg?1438010518) This inspiring video walks us through the making of a smooth leather cover for the Moleskine notebook. Watch as a simple piece of leather becomes a classy cover for all those world-changing thoughts. I've carried a pocket notebook with me for years. It's been a constant message to me that my thoughts matter, that I have something to say, and also that I need to keep track of my grocery list. This little notebook means a lot to me, so a protective cover makes sense. Here's a beautiful video of Kinnari leather crafting a simple but complex cover for his Moleskine.

This inspiring video walks us through the making of a smooth leather cover for the Moleskine notebook. Watch as a simple piece of leather becomes a classy cover for all those world-changing thoughts. I've carried a pocket notebook with me for years. It's been a constant message to me that my thoughts matter, that I have something to say, and also that I need to keep track of my grocery list. This little notebook means a lot to me, so a protective cover makes sense. Here's a beautiful video of Kinnari leather crafting a simple but complex cover for his Moleskine.

![credit: Food.com [http://www.food.com/recipe/olive-garden-copycat-zuppa-toscana-38298?photo=57552] Zuppa Toscana](http://assets.manmadediy.com/photos/26534/picu25Bsa_large.jpg?1437728063)

![credit: damndelicious.net [http://damndelicious.net/2014/05/30/pf-changs-chicken-lettuce-wraps/] Lettuce Wrap](http://assets.manmadediy.com/photos/26535/IMG_0508edit_large.jpg?1437728065) 5.

5.![credit: Australia Plunge Pools [http://australianplungepools.com.au/projects.php?id=22] Small Pool Plunge](http://assets.manmadediy.com/photos/26591/76C5EFC1-F014-4C86-B99D-46FDC99A94A9_large.png?1438552597)

![credit: My Paradissi [http://www.myparadissi.com/2015/05/10-backyard-pools-to-steal-your-heart.html] Small Backyard Pool](http://assets.manmadediy.com/photos/26596/backyard-pools-to-steal-your-heart-maldives-happily-grey_large.jpg?1438576518)

![credit: Decormag [http://www.decormag.com/MaisonJardin/exterieurs/le-jardin-secret-de-mario-lafrenais-de-moine-urbain-n38327358p5.html] Backyard Pool](http://assets.manmadediy.com/photos/26597/zC-mar129559_large.jpg?1438576523)

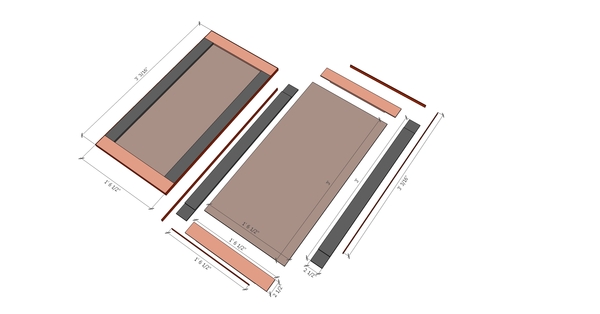

![credit: David [manmadediy.com] Cabinet Layout](http://assets.manmadediy.com/photos/26598/Single%20Wall%20Cabinet_large.jpg?1438578761) SketchUp is a great program for getting a project started. From the 3D visualization, all the way down to generating cut lists here's an overview on how it works for us woodworkers. I've been working hard on planning out my workshop upgrades over here. It's been a long time coming and I'm so happy to be started. SketchUp has been essential to making my shop at least a virtual reality at this point. I've laid out each component in it's own model and now I've been able to measure, adjust, and generate a material list and cut sheet for each part of the project. I just finished building my carcasses for the hanging wall cabinets and can say I had almost no adjustments to do in the shop that weren't already laid out well in the model.

SketchUp is a great program for getting a project started. From the 3D visualization, all the way down to generating cut lists here's an overview on how it works for us woodworkers. I've been working hard on planning out my workshop upgrades over here. It's been a long time coming and I'm so happy to be started. SketchUp has been essential to making my shop at least a virtual reality at this point. I've laid out each component in it's own model and now I've been able to measure, adjust, and generate a material list and cut sheet for each part of the project. I just finished building my carcasses for the hanging wall cabinets and can say I had almost no adjustments to do in the shop that weren't already laid out well in the model.![credit: David [manmadediy.com] Exploded View](http://assets.manmadediy.com/photos/26599/Single%20Wall%20Cabinet%20Exploded_large.jpg?1438579476)

![credit: David [manmadediy.com] SketchUp Screenshot](http://assets.manmadediy.com/photos/26600/Screenshot_large.jpg?1438580000)

Love the thought of making useful and beautiful pieces out of leather? Here are the first few steps to get started down the path of making your own essential carry pieces and everyday items from that timeless and durable material.

Love the thought of making useful and beautiful pieces out of leather? Here are the first few steps to get started down the path of making your own essential carry pieces and everyday items from that timeless and durable material. 1. Knife - A sharp and precise knife is important for accurately slicing those pieces to size. Have a medium #2 X-Acto knife for the small cuts, and a larger moredurable break-away razor utility knife for more comfortable cutting on the bulk of the pattern.

1. Knife - A sharp and precise knife is important for accurately slicing those pieces to size. Have a medium #2 X-Acto knife for the small cuts, and a larger moredurable break-away razor utility knife for more comfortable cutting on the bulk of the pattern. 4. Work Surface - A clean, flat, and forgiving surface is great to make sure everything laysout right. Cork is a soft, grippy, and natural surface that works great, but can get torn up rather easily. If your workspace is used for more then just leather work, go for a pvc cutting pad so you can move and store it easily. Not as soft or grippy, but it is self healing and will survive some abuse.

4. Work Surface - A clean, flat, and forgiving surface is great to make sure everything laysout right. Cork is a soft, grippy, and natural surface that works great, but can get torn up rather easily. If your workspace is used for more then just leather work, go for a pvc cutting pad so you can move and store it easily. Not as soft or grippy, but it is self healing and will survive some abuse.![credit: Bat House by Estudio Estres [http://www.estudioestres.com/estudio/]](http://assets.manmadediy.com/photos/26647/lugheqg2zkxe4sxipdu8_large.jpg?1439408316)

![credit: Gaiam [] Bat House](http://assets.manmadediy.com/photos/26637/home_for_bats1_large.jpg?1439192952)

![credit: Natures Way [http://www.natureswaybirds.com/products/bat-house-triple-chamber] Bat House](http://assets.manmadediy.com/photos/26638/61GRJHZ30uL._SL1280__large.jpg?1439193006)

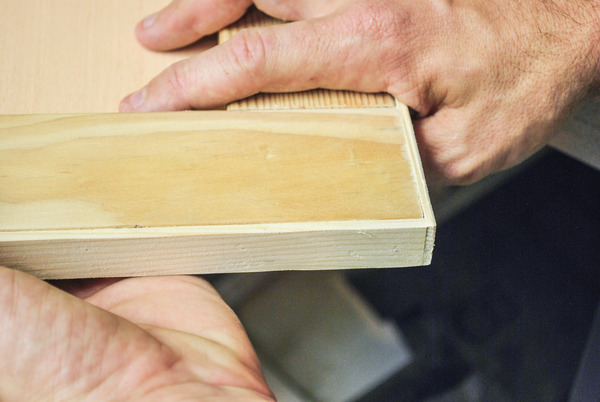

It's time to actually build something for the shop upgrade. First up, we take a look at how to build wall cabinets from scratch (sheet goods at least).

It's time to actually build something for the shop upgrade. First up, we take a look at how to build wall cabinets from scratch (sheet goods at least).

The clean slate of a freshly painted wall was the perfect background to build my three wall cabinets.

The clean slate of a freshly painted wall was the perfect background to build my three wall cabinets. I built my cabinets in three distinct pieces: The carcass, the face frame, and the doors.

I built my cabinets in three distinct pieces: The carcass, the face frame, and the doors.

I also cut a 1/4” groove ¾” from the back edge on all pieces to account for the plywood back panel and to give room for the mounting boards to integrate on the top and bottom.

I also cut a 1/4” groove ¾” from the back edge on all pieces to account for the plywood back panel and to give room for the mounting boards to integrate on the top and bottom.

You can drill mounting screws directly through the back panel into the wall studs, but I prefer to use the French cleat method. This is a great technique for a few reasons: first, it’s much easier to line up the French cleat level and at the right height than it is to get the cabinet in place and drill through the panel into the stud. Second, there is some side-to-side play with a French cleat so you can snug up the cabinets to each other. Lastly, it’s a strong joint that holds well but can be easily removed in the future if things change.

You can drill mounting screws directly through the back panel into the wall studs, but I prefer to use the French cleat method. This is a great technique for a few reasons: first, it’s much easier to line up the French cleat level and at the right height than it is to get the cabinet in place and drill through the panel into the stud. Second, there is some side-to-side play with a French cleat so you can snug up the cabinets to each other. Lastly, it’s a strong joint that holds well but can be easily removed in the future if things change.

This piece was mounted with the angle facing the wall leveled with 4 long screws through the studs for support. Once it is installed, it’s a simple matter to put the cabinet on the wall and lower onto the cleat for a sturdy mount. I add two screws through the bottom mounting board along the bottom edge to keep it secured to the wall.

This piece was mounted with the angle facing the wall leveled with 4 long screws through the studs for support. Once it is installed, it’s a simple matter to put the cabinet on the wall and lower onto the cleat for a sturdy mount. I add two screws through the bottom mounting board along the bottom edge to keep it secured to the wall.

![credit: David [manmadediy.com] X-Table PB Inspired](http://assets.manmadediy.com/photos/26636/540997_10150931570458687_861066275_n_large.jpg?1439189792) A few years ago my wife handed me a catalog and told me she "must have" the table inside. After I took a look at the design (and the price tag), I was inspired to build it myself. While I love the style of Pottery Barn's furniture, it's never been in my budget to fill my house with their excellent products. But when my wife showed me the wide, welcoming table that would help us better entertain at our house, she was ready to make the purchase. Having just claimed the garage as my own, I was eager to make this myself. So despite my wife's doubt, I set out to make it.

A few years ago my wife handed me a catalog and told me she "must have" the table inside. After I took a look at the design (and the price tag), I was inspired to build it myself. While I love the style of Pottery Barn's furniture, it's never been in my budget to fill my house with their excellent products. But when my wife showed me the wide, welcoming table that would help us better entertain at our house, she was ready to make the purchase. Having just claimed the garage as my own, I was eager to make this myself. So despite my wife's doubt, I set out to make it.![credit: David [manmadediy.com] My Dining Table](http://assets.manmadediy.com/photos/26635/575449_10150931570378687_1929531565_n_large.jpg?1439189703)

![credit: Clearwood Paddleboards [http://clearwoodpaddleboards.com/] Clearwood Paddleboard](http://assets.manmadediy.com/photos/26709/woodShapingWithChiselCloseup_large.jpg?1439787027) As summer gives us just a few more weeks of dependable warmth, I’ve been hitting the water as much as life will allow. But soon enough it will be much too cold for getting wet and so here’s a project to get on now so when spring comes back around, we’ll be ready to once again enjoy a day on the water.

As summer gives us just a few more weeks of dependable warmth, I’ve been hitting the water as much as life will allow. But soon enough it will be much too cold for getting wet and so here’s a project to get on now so when spring comes back around, we’ll be ready to once again enjoy a day on the water. ![credit: CLC Boats [http://www.clcboats.com/shop/boats/surf_boats/kaholo-stand-up-paddleboard.html] Putting on the back](http://assets.manmadediy.com/photos/26710/phpThumb_large.php?1439787031)

![credit: Clearwood Paddleboards [http://clearwoodpaddleboards.com/] Progess](http://assets.manmadediy.com/photos/26711/shopViewHollowWoodBoardInProgress_large.jpg?1439787032)

![credit: CLC Boats [http://www.clcboats.com/shop/boats/surf_boats/kaholo-stand-up-paddleboard.html] Sanded Paddleboard](http://assets.manmadediy.com/photos/26712/phpThumb_large.php?1439787036)

![credit: CLC Boats [http://www.clcboats.com/shop/boats/surf_boats/kaholo-stand-up-paddleboard.html] Putting on the fiberglass](http://assets.manmadediy.com/photos/26713/phpThumb_large.php?1439787041)

![credit: Lumberjocks [http://lumberjocks.com/projects/98376] taper Cutting jig](http://assets.manmadediy.com/photos/26714/469370-438x_large.jpg?1439791153) I spend quite a bit of time setting up for projects on the tools. It’s amazing how much time it takes to make a few simple yet complex cuts. For the type of cuts that happen often, it makes sense to make a few go-to jigs to help with those annoying set-ups. One of my favorite places to find jigs and other ideas is

I spend quite a bit of time setting up for projects on the tools. It’s amazing how much time it takes to make a few simple yet complex cuts. For the type of cuts that happen often, it makes sense to make a few go-to jigs to help with those annoying set-ups. One of my favorite places to find jigs and other ideas is ![credit: Popular Woodworking [http://www.popularwoodworking.com/projects/tablesawn-circles] circle cutting jig](http://assets.manmadediy.com/photos/26715/fred_TablesawnCirclesFigA_large.png?1439791156)

![credit: Lumberjocks [http://lumberjocks.com/projects/98376] Taper Cutting Jig](http://assets.manmadediy.com/photos/26716/n2994jf_large.jpg?1439791158)

![credit: Lumberjocks [http://lumberjocks.com/projects/77126] Box Joint jig](http://assets.manmadediy.com/photos/26717/mg5412z_large.jpg?1439791162)

![credit: Becky J. [http://apeacefuldwelling.blogspot.com/2012/02/cast-iron-cinnamon-rolls.html] Tasty Cinnamon Rolls](http://assets.manmadediy.com/photos/26719/DSC_10811_large.jpg?1439831485)

![credit: James Long [http://www.jameslongfurniture.co.uk/work.html#] Beautiful Joint](http://assets.manmadediy.com/photos/26768/full5_large.jpg?1440405516) I recently picked up a new dovetail jig to make some drawers. After getting the basics under control I took a look around at some of the more artful joints out there. I definitely have a ways to go.

I recently picked up a new dovetail jig to make some drawers. After getting the basics under control I took a look around at some of the more artful joints out there. I definitely have a ways to go.![credit: Woodhacker [http://lumberjocks.com/Woodhacker/blog/5139] Double Dovetail](http://assets.manmadediy.com/photos/26769/P6150103_large.jpg?1440405520)

![credit: Finewoodworking [http://www.finewoodworking.com/how-to/article/how-to-cut-sliding-dovetail-joints.aspx] Rabbeted Dovetail](http://assets.manmadediy.com/photos/26770/99933248-sliding-dovetails_03_large.jpg?1440405522)

![credit: Ncio Yektai [http://nicoyektai.com/other/leaning-dovetails.html] Funky Looking Joints](http://assets.manmadediy.com/photos/26771/leaning-dovetails-detail-800_large.jpg?1440405524)

![credit: Caila Made [cailamade.com/leather-tool-roll-diy-giveaway/] Leather Tool Case](http://assets.manmadediy.com/photos/26764/DSC08065_large.jpg?1440401860) A few weeks back we talked about some of t

A few weeks back we talked about some of t![credit: Design Sponge [http://www.designsponge.com/2011/08/diy-project-hand-sewn-passport-cover.html] Passport Cover](http://assets.manmadediy.com/photos/26765/woodfaulk_passport_cover11_large.jpg?1440401865)

![credit: Doodlecraft [http://www.instructables.com/id/Leather-Mason-Jar-Mug-Coozie/] Leather Cup Holder](http://assets.manmadediy.com/photos/26766/FWSRKLLHWDRE2L6.LARGE_large.jpg?1440401869)

![credit: Caila Made [http://cailamade.com/leather-tool-roll-diy-giveaway/] Leather Roll-Up Case](http://assets.manmadediy.com/photos/26767/DSC08118_large.jpg?1440401872)

![credit: The Art of Manliness [http://www.artofmanliness.com/2015/04/02/diy-pocket-notebooks-from-six-pack-cartons/] DIY Pocket Notebook](http://assets.manmadediy.com/photos/26772/IMG_3409_large.jpg?1440406653) 6 pack cases - we all have a few of those around, the remnants of a night with friends and now the perfect cover for your pocket notebook. I always feel a bit bad about throwing out those artfully crafted 6 pack holders from my favorite craft brewery. I also use plenty of small notebooks at work and play so they tend to get ragged pretty fast without a nice cover.

6 pack cases - we all have a few of those around, the remnants of a night with friends and now the perfect cover for your pocket notebook. I always feel a bit bad about throwing out those artfully crafted 6 pack holders from my favorite craft brewery. I also use plenty of small notebooks at work and play so they tend to get ragged pretty fast without a nice cover.![credit: The Art of Manliness [http://www.artofmanliness.com/2015/04/02/diy-pocket-notebooks-from-six-pack-cartons/] The Tools](http://assets.manmadediy.com/photos/26773/IMG_3399_large.jpg?1440406655)

To share our picks, we teamed up with

To share our picks, we teamed up with

Add the dry ingredients into the mix and lightly blend together. Be careful not to over-blend, as the sauce can go from creamy to runny in a blink.

Add the dry ingredients into the mix and lightly blend together. Be careful not to over-blend, as the sauce can go from creamy to runny in a blink.

Chop up the cabbage, cilantro, onions, and avocado. Section out the cabbage and cilantro into separate bowls and mix the remaining ingredients together.

Chop up the cabbage, cilantro, onions, and avocado. Section out the cabbage and cilantro into separate bowls and mix the remaining ingredients together.

![credit: Woodgears [http://woodgears.ca/pantograph/build.html] Finished Pantograph](http://assets.manmadediy.com/photos/26851/half_setting_large.jpg?1440825934)

![credit: Eightsevencentral.com [http://eightsevencentral.com/wp/assets/screenprint.jpg] Screen Printing](http://assets.manmadediy.com/photos/26847/screenprint_large.jpg?1440820980) We all come in contact with screenprinted goods every day... there's a good chance you're wearing something screenprinted right now. It's is an impressive way to personalize just about anything you can think of, and it's really not that hard to start. Here are a few starter kits to help start down the road to making your own art and customizing everything you can get your hands on.

We all come in contact with screenprinted goods every day... there's a good chance you're wearing something screenprinted right now. It's is an impressive way to personalize just about anything you can think of, and it's really not that hard to start. Here are a few starter kits to help start down the road to making your own art and customizing everything you can get your hands on. ![credit: Screenprinting.com [http://www.screenprinting.com/diy-print-shop-t-shirt-kit#.VeEoffTdVGG] DIY Print Shop Kit](http://assets.manmadediy.com/photos/26844/DIY-Print-Shop-3_large.jpg?1440820037)

![credit:Blicks [http://www.dickblick.com/products/blicks-complete-photofabric-screen-printing-kit/?PID=2270134&Ref=CJ&source=affiliate&CID=1973836&Publisher=Joshua+Van+Horsen&Blick_affiliate=1973836&CA_6C15C=520010530000126075#photos] Screen Printing Kit](http://assets.manmadediy.com/photos/26848/44907-1009-5-3ww-l_large.jpg?1440820982)

![credit: Amazon.com [http://www.amazon.com/dp/B00MHPJ16K/ref=asc_df_B00MHPJ16K3806007?smid=ATVPDKIKX0DER&tag=pricegrabbe05-20&linkCode=df0&creative=395097&creativeASIN=B00MHPJ16K&ascsubtag=1440821061_c343582fae776694ef377f69e51e2830_2006_402_1665678368_6919] Amazon Screen Printing Kit](http://assets.manmadediy.com/photos/26849/61zeWOoPtdL._SX425__large.jpg?1440821252)

There are plenty of shelves in my shop that need doors to keep out the dust, and to keep the look of the shop more streamlined. These cheap doors are made from 2.5" pine boards and affordable 1/4" plywood. They still look great and function well, and they have enough heft to feel strong in your hand.

There are plenty of shelves in my shop that need doors to keep out the dust, and to keep the look of the shop more streamlined. These cheap doors are made from 2.5" pine boards and affordable 1/4" plywood. They still look great and function well, and they have enough heft to feel strong in your hand.  1. Measure them out - the doors should overhang the openings by about 1/2" on the outside edges and the top and bottom. This means you should measure the door openings, and add 1" for the top measurement and 1/2" for the hinge side of the doors.

1. Measure them out - the doors should overhang the openings by about 1/2" on the outside edges and the top and bottom. This means you should measure the door openings, and add 1" for the top measurement and 1/2" for the hinge side of the doors.

![credit: Bole Tannery [http://www.boletannery.com/bole/leather/] created at: 09/08/2015](http://assets.manmadediy.com/photos/26929/leather_large.jpg?1441749184) Bole Tannery

Bole Tannery![credit: Bole Tannery [http://www.boletannery.com/rucksacks/gallery/] Rucksack](http://assets.manmadediy.com/photos/26891/Bole-nov-2013_5377-WEB_large.jpg?1441607887)

![credit: Bole Tannery [http://www.boletannery.com/briefcases/double-minister-briefcase/] Minister Briefcase](http://assets.manmadediy.com/photos/26892/Bole-nov-2013_5337-WEB-dubbel1_large.jpg?1441607893)

![credit: Bole Tannery [http://www.boletannery.com/briefcases/] Tanning Leather](http://assets.manmadediy.com/photos/26893/B%25C3%25B6le7056-WEB1_large.jpg?1441607900)